OVERVIEW

Seismic isolation is the structural mechanism that decouples a building or structure from potentially damaging earthquakes or other causes of motion at the supports. The decoupling is achieved by increasing the flexibility of the system, while providing appropriate damping.

In many applications, a seismic isolating system is mounted beneath the structure and is referred to as the ‘base isolation.’ The most common technology is the lead rubber bearing (LRB), which decouples the structure from the foundation. Other products that have been developed and patented include dampers and sliders, which absorb or dissipate movement. Seismic isolation installation costs are in the range of 2% to 5% of total construction costs. It is a proven technology that has successfully protected buildings from earthquakes in the US and in Japan.

Also it is a proven technology that has been accepted and applied in many countries around the world. Advanced technologies are also being developed, which can perform similarly to the original LRB’s, but for different situations at different costs.

Recently, research and applications of the seismic isolating systems that act as a passive control of vibrations due to dynamic loads are actively conducted. Seismic isolators minimize damage due to dynamic loads in large structures, such as buildings, bridges and nuclear power plants.

Due to the effectiveness of these isolators, advanced countries are implementing seismic isolation design to improve structural safety, and this is becoming a common practice. Various dynamic loads, including seismic loads, wind loads, moving loads and vibrations from vehicles and plant equipment can cause structural distress. Therefore, engineers are becoming aware of considering seismic isolation systems in controlling vibrations due to such dynamic loads is gradually increasing. Also, seismic isolating systems are implemented in various areas such as semiconductor factories, large computer centers, precision counting rooms, etc., which use ground vibration control for non-vibration clean rooms and vibration isolating devices for foundations of vibrating equipment.

In this technical guide, modeling seismic isolators, theoretical background and seismic isolation analysis in midas Gen are introduced. Also, the application and effectiveness are demonstrated with an analytical exercise, i.e. the analysis of a building with seismic isolators installed.

Introduction to Seismic Isolation Analysis Using MIDAS Software

The Future of Technology in India

India can be perceived as a conundrum when it comes to earthquake engineering. It has produced some of the finest structural engineers in the world, and yet, it has not addressed all of the fundamental problems in some parts of the country. India follows its own building code, but also compromises to certain extent between engineering design and construction.

The country is mapped out with seismic zones that are not probabilistically based, but experts are available to develop such a zoning map. In the end, it appears that there is currently a lack of consensus on the correct approach to be taken. On January 26th, 2001, the Republic Day of India, an earthquake in the Kutch region of Gujarat devastated a middle-class community situated some 300 km from the epicenter. Due to this catastrophe, some residents are now considering to invest in housing with improved seismic resistance.

The first large building to be base isolated in India is the new 300-bed, Bhuj District Hospital, a replacement for the one destroyed in the Gujarat earthquake. Members of the Wellington-based Earthquake Engineering NZ business cluster have worked closely with Indian engineers and contractors in developing both the design of the base isolating system for this hospital and installation of the customized bearings.

The original Bhuj District Hospital collapsed in the massive earthquake that hit the city, perished almost all 176 patients and many members of the staff. The replacement hospital is supported by Robinson Seismic Lead Rubber Bearings, which will ensure the structural stability of the hospital, allowing it to remain operational following future seismic activities.

Seismic Isolator & Seismic Isolation Analysis Fundamentals

A seismic isolator is an intermediate vibration control device that minimizes the transfer of vibration to the structure. It is usually installed at the main vibration transfer medium between the structure and the foundation, or between the pier and superstructure of a bridge.

Seismic isolation buffers a structure from horizontal ground motion by installing structural material of low horizontal stiffness between the structure and its foundation. This induces the vibration period of the structure with seismic isolation greater than that of the structure with a fixed foundation. The 1st dynamic mode of a structure with seismic isolation includes only the deformation of the seismic isolators and the rigid behavior of the superstructure. Structural deformation occurs at higher modes, and the high vibration energy of the ground at low vibration periods is not transferred to the structure. This is due to the fact that higher modes do not dominate the behavior of the structure. From the dynamics perspective, the vibration period of the entire structure increases when flexible material at the foundation is installed. Due to the increase in the response spectrum period, the acceleration is minimized, which in turn, minimizes the base shear force.

The problem, however, is that severe deformation can result near the seismic isolation. Because of this issue, collision against other adjacent structures, piping damage and buckling of equipment can lead to structural instability; therefore, a displacement limit is required. The higher the displacement limit of the seismic isolators, the greater will be their energy dissipative ability. The displacement limit can be obtained from the reduction of displacement, according to the adjustment of the damping ratio for the displacement from the response spectrum. The energy dissipative property of the material itself will additionally reduce the displacement.

Generally, a seismic isolating system requires the following basic properties:

1) Material flexibility that increases the vibration period of the structure under loading

2) The ability to dissipate energy, reducing displacement

3) Stiffness for wind loads, ambient vibrations, or vibrations due to small loads

Other aspects, such as deformation due to temperature, restoration, maintenance costs, etc., are matters that can be considered for seismic isolating equipment.

Seismic isolating systems are practical for middle to low-rise buildings and bridge structures because these structures have short periods. If the frequency of a seismic load matches the natural frequency of a structure, this will result in catastrophic damage. Seismic isolation dampens the natural frequency response of the structure, preventing this consequence. For high-rise buildings, however, large overturning moments can occur due to vibration; thus, seismic isolating equipment usually does not have the necessary tensile strength for these cases.

Seismic Isolators Featured in MIDAS Software

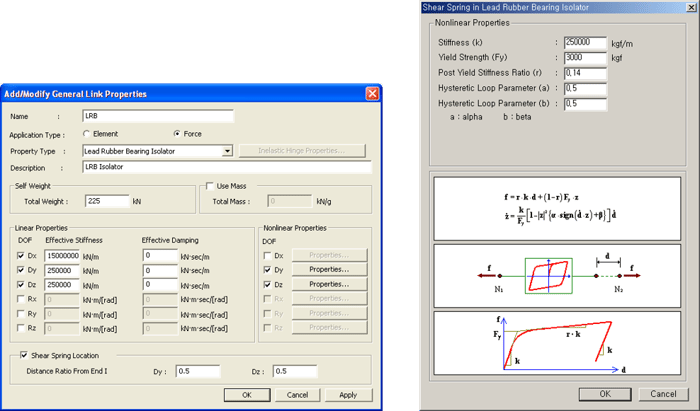

The seismic isolators that are available in MIDAS software are the commonly used Lead Rubber Bearing (LRB) and Friction Pendulum System (FPS). The characteristics of both seismic isolators are explained in the following subsections.

Lead Rubber Bearing (LRB)

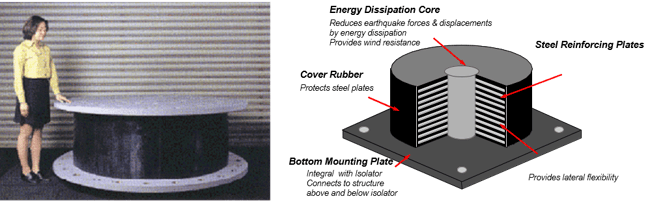

The LRB is the most common seismic isolator. It is normally made with rubber vulcanized between two steel plates, as shown in figure 1. The damping range of the rubber is from 5% to 15% (10% being recommended standard for the damping of rubber). A lead core provides an additional 30% of damping. The lead core provides a means of handling extremely large displacements by increasing initial stiffness and energy dissipative characteristics of the isolator. It also provides additional damping through plastic deformation of the top and bottom steel plates. The rubber provides a restoration force when the lead core yields, while the yielding of the lead core increases the vibration period of the structure.

Figure 1. Lead Rubber Bearing (LRB) Seismic Isolator

Figure 1. Lead Rubber Bearing (LRB) Seismic IsolatorMIDAS software defines LRB seismic isolators (shown in figure 2) with bi-axial plastic deformation in two shear directions. The other four degrees of freedom behave as linear elastic springs, which are mutually independent.

Please download White Paper VOL.14 for Fundamentals of Seismic Isolation Analysis below to see the full contents.

Banner Title Products

Banner Title Products