OVERVIEW

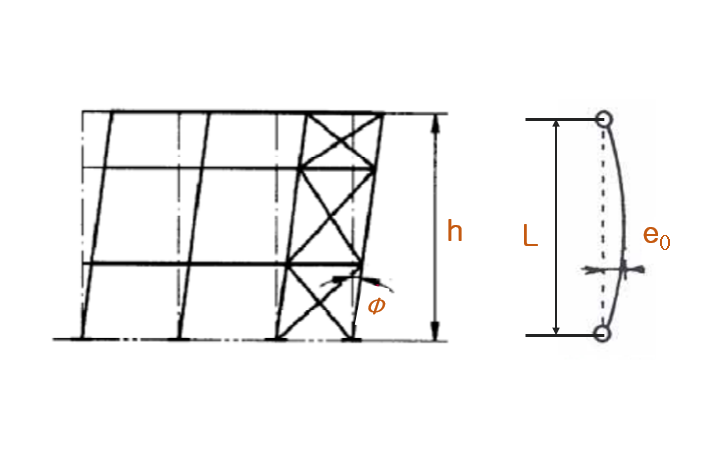

In high-rise buildings, the axial deformations of columns cannot be ignored, and special considerations are required for design and construction. A vertical member undergoes both elastic deformation and deformation due to creep and shrinkage. The elastic deformation takes place instantaneously due to dead loads and live loads applied to the structure, while deformation due to creep and shrinkage occurs over many years. Most of the vertical deformations in a high-rise building, however, take place during its construction.

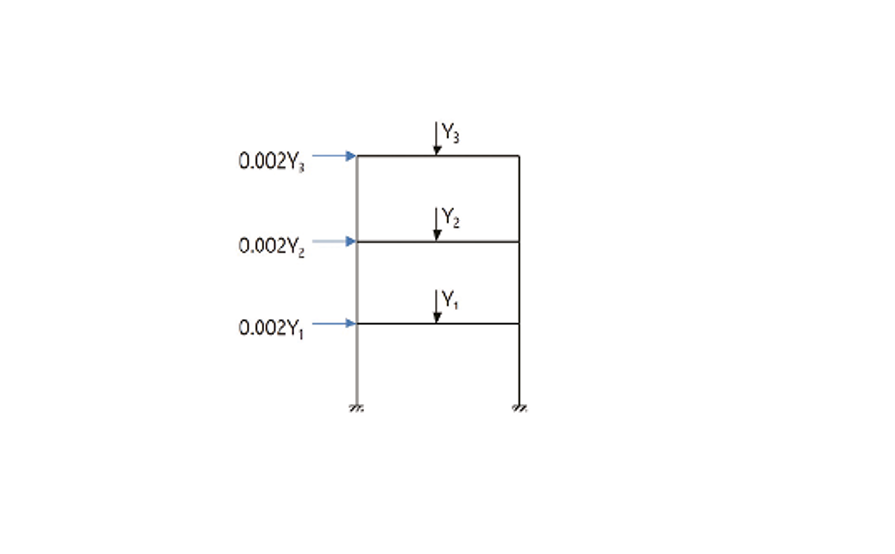

Due to the difference in axial stiffness and load distribution areas on vertical members, differential shortening inevitably develops. If this differential shortening in vertical members, which takes place during and after the construction, is not considered in analyses of high-rise buildings, structural safety will be compromised due to additional stresses in the horizontal members and, subsequently, in the vertical members. The structural safety problem is also magnified when incorporating serviceability issues such as the curtain wall function, floor unevenness, excess stress in piping, etc. As such, total displacements of vertical members must be calculated at the design stage. Comparatively reasonable and accurate results can be predicted when construction stage analysis is carried out reflecting the creep and shrinkage behavior of concrete.

Conventional structural analysis has the assumption that all structural loads are instantaneously applied to the entire completed structure. However, since most buildings are constructed by one story or several floor units at a time, or even if it is the same story, the construction sequence and loading sequence may be different depending on the construction plan. Therefore, the actual structural behavior can be significantly different from the conventional analytical behavior based on the above assumption.

Vertical members (columns and walls) in high-rise reinforced concrete buildings not only exhibit elastic shortening, but also have shrinkage and creep effects that develop from long-term compressive loading. In lower stories of a building, additional stresses in girders become very large due to differential shortening and undergo significant redistribution of the member forces.

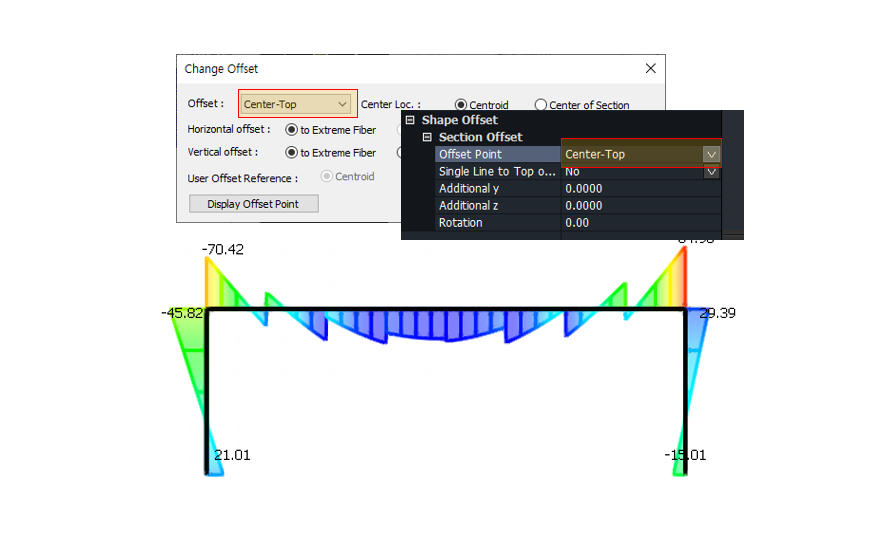

In order to analytically solve the problem described above, the construction stage analysis function of midas Gen considers shrinkage and creep during construction stages to simulate the construction process of a high-rise building. Also, with input variables, such as the strength of concrete, construction duration of building components, casting condition, ambient condition, etc., the elastic shortening, shrinkage and creep of vertical members can be estimated and are reflected in the analysis. Change in strength gain based on the maturity of concrete members is also reflected in the calculation of modulus of elasticity at various construction stages.

In the following example, construction stage analysis considers the creep and shrinkage effects of a 40-story building consisting of an exterior concrete frame and interior shear walls, as shown in figure 1. The displacements of vertical members and the girder member forces are compared and evaluated with the results from conventional analysis (analysis in which construction stages are not considered.).

You can download the e-book file at the end of this page!😊

Structural System

The structural system, as shown in figure 1, is a 40-story building constructed with core walls and perimeter RC columns & RC girders. In order to evaluate the influence that gravity has on the displacements of a vertical member, and the member forces of horizontal members, the member sections are selected according to the dead load and the live load. The typical plan view of a story is shown in figure 2.

Figure 1. 3D Analysis Model

Figure 2. Typical Story Plan View

Design Loads

|

Type of Loads |

Symbols |

Loads |

|

Frame Self Weight |

SW |

- |

|

Slab Self Weight |

Dc |

360kgf/m2 |

|

Finishing and Masonry Loads |

Ds |

160kgf/m2 |

|

Live Loads |

LL |

250kgf/m2 |

Construction Sequence

|

Stage |

Element Group |

Stage Load |

Duration (days) |

Total Construction Period (days) |

Description |

|

|

#CS1 |

1st Fl. Core |

|

SW/Dc |

5 |

5 |

|

|

#CS2 |

2nd Fl. Core |

|

SW/Dc |

5 |

10 |

|

|

#CS3 |

3rd Fl. Core |

|

SW/Dc |

5 |

15 |

|

|

#CS4 |

4th Fl. Core |

1st Fl. Frame |

SW/Dc |

5 |

20 |

|

|

#CS5 |

5th Fl. Core |

2 Fl. Frame |

SW/Dc |

5 |

25 |

|

|

#CS6 |

6th Fl. Core |

3 Fl. Frame |

SW/Dc |

5 |

30 |

|

|

#CS7 |

7th Fl. Core |

4 Fl. Frame |

SW/Dc |

5 |

35 |

|

|

… |

… |

… |

… |

… |

… |

|

|

#CS21 |

21st Fl. Core |

18 Fl. Frame |

SW/Dc/Dd |

5 |

105 |

1st Fl. Int. Finishing |

|

#CS22 |

22nd Fl. Core |

19 Fl. Frame |

SW/Dc/Dd |

5 |

110 |

2nd Fl. Int. Finishing |

|

… |

… |

… |

… |

… |

… |

… |

|

#CS40 |

40th Fl. Core |

37 Fl. Frame |

SW/Dc/Dd |

5 |

200 |

20th Fl. Int. Finishing |

|

#CS41 |

|

38 Fl. Frame |

SW/Dc/Dd |

5 |

205 |

21st Fl. Int. Finishing |

|

#CS42 |

|

39 Fl. Frame |

SW/Dc/Dd |

5 |

210 |

22nd Fl. Int. Finishing |

|

#CS43 |

|

40 Fl. Frame |

SW/Dc/Dd |

5 |

215 |

23rd Fl. Int. Finishing |

|

#CS44 |

|

|

Dd |

85 |

300 |

24~40 Fl. Int. Finishing |

|

#CS45 |

|

|

|

90 |

390 |

|

|

#CS46 |

|

|

LL |

260 |

650 |

Live Loads |

Figure 3. Sequence of Construction Stages

Material Properties

In order to define the properties of concrete shrinkage and creep, the ACI standard is used, and the concrete material properties are shown in this table.

|

Column |

Comp. Strength (kgf/cm2) |

Humidity (%) |

Slump (cm) |

Aggregate (%) |

Air (%) |

Cement (kg/m3) |

V/S Ratio (mm) |

Code |

|

C1 (1~5th) |

500 |

55 |

12 |

60 |

4.5 |

450 |

300 |

ACI |

|

C1 (6~10th) |

500 |

55 |

12 |

60 |

4.5 |

450 |

275 |

ACI |

|

C1 (11~15th) |

400 |

55 |

12 |

60 |

4.5 |

380 |

250 |

ACI |

|

C1 (16~20th) |

400 |

55 |

12 |

60 |

4.5 |

380 |

225 |

ACI |

|

C1 (21~25th) |

350 |

55 |

12 |

60 |

4.5 |

350 |

200 |

ACI |

|

C1 (26~30th) |

350 |

55 |

12 |

60 |

4.5 |

350 |

175 |

ACI |

|

C1 (31~35th) |

300 |

55 |

12 |

60 |

4.5 |

320 |

150 |

ACI |

|

C1 (36~40th) |

300 |

55 |

12 |

60 |

4.5 |

320 |

125 |

ACI |

|

C2 (1~10th) |

500 |

55 |

12 |

60 |

4.5 |

450 |

225 |

ACI |

|

C2 (11~20th) |

400 |

55 |

12 |

60 |

4.5 |

380 |

200 |

ACI |

|

C2 (21~30th) |

350 |

55 |

12 |

60 |

4.5 |

350 |

175 |

ACI |

|

C2 (31~40th) |

300 |

55 |

12 |

60 |

4.5 |

320 |

150 |

ACI |

|

Girder G1 |

270 |

55 |

12 |

60 |

4.5 |

302 |

127 |

ACI |

|

Girder G2 |

270 |

55 |

12 |

60 |

4.5 |

302 |

100 |

ACI |

|

Link beam |

270 |

55 |

12 |

60 |

4.5 |

302 |

127.3 |

ACI |

|

Wall (1~10th) |

500 |

55 |

12 |

60 |

4.5 |

450 |

266 |

ACI |

|

Wall (11~20th) |

400 |

55 |

12 |

60 |

4.5 |

380 |

266 |

ACI |

|

Wall (21~30th) |

350 |

55 |

12 |

60 |

4.5 |

350 |

226 |

ACI |

|

Wall (31~40th) |

300 |

55 |

12 |

60 |

4.5 |

320 |

226 |

ACI |

The concrete creeps coefficient data and graph, as well as the shrinkage strain data and graph, as per the ACI standard, are shown in figure 4 and figure 5, respectively.

Figure 4. Concrete Creep Coefficient Data & Graph by ACI Code

Figure 5. Shrinkage Strain Data & Graph by ACI Code

If you would like to keep reading this article, please download the VOL.08 White Paper below.